INDUSTRY SOLUTIONS

Quality Prediction

Q-Metric is an innovative system developed for quality optimization in production facilities that continuously monitors, improves and saves significant amount of raw materials using advanced data collection and analysis techniques.

Benefits

- Long-drawn out laboratory processes are accelerated.

- Product quality is monitored instantly.

- Quality problems that may occur are foreseen.

- Production quality is controlled while raw material and energy saving is provided.

Data Collecting

All process data affecting product quality are recorded in real time. All data obtained from the quality control process are mapped to the production process data and kept in the system

Learning

By using learning algorithms, mathematical models are trained according to product types and corresponding quality characteristics to be followed. Learning process continues automatically as long as production continues.

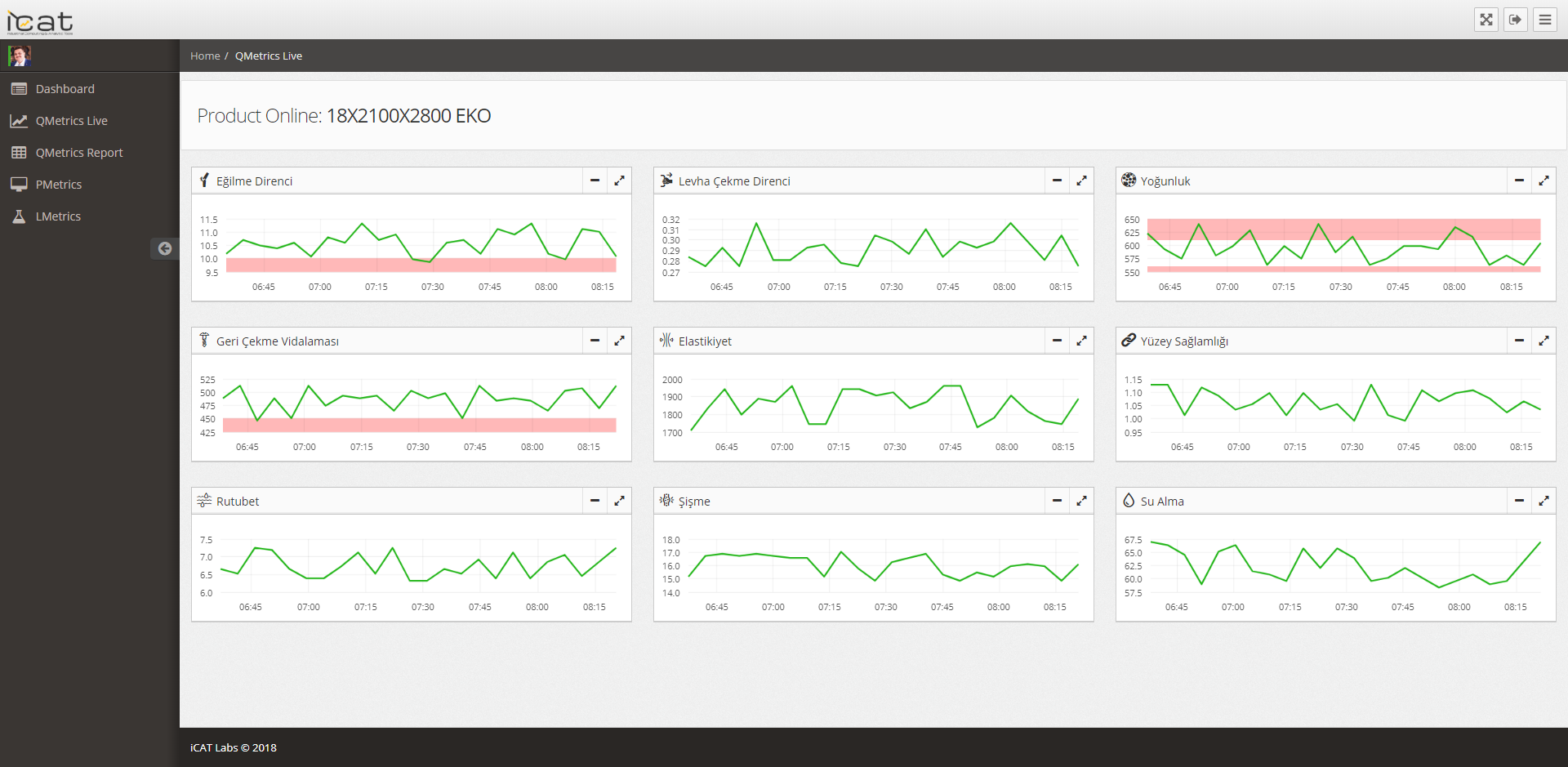

Quality Prediction

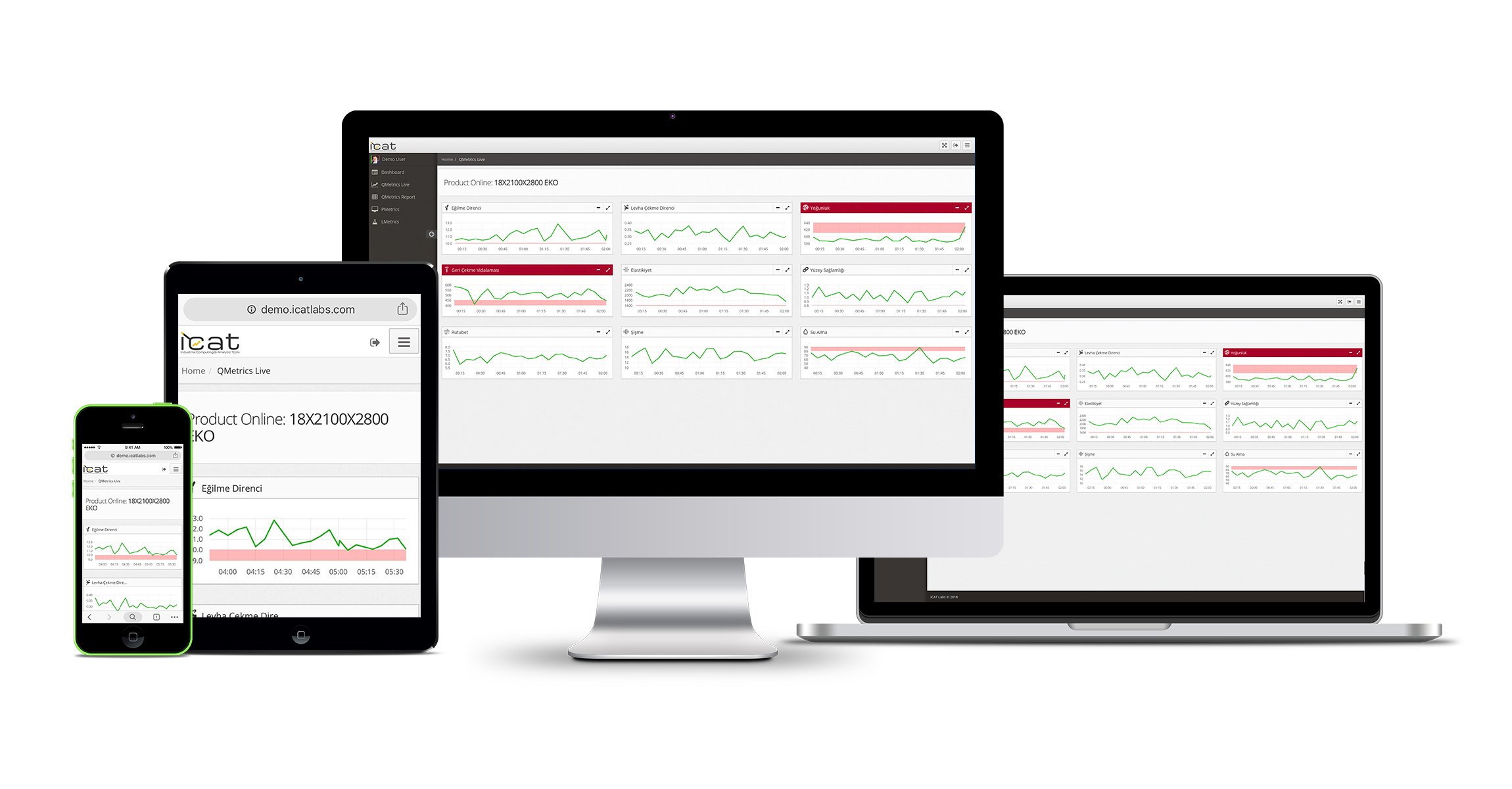

Learned models are fed with real-time values from production. Results can be tracked on computers, tablets and mobile phones via a web interface. As the operator changes the production parameters (speed, temperature, raw material used, etc.), the system results are instantly updated.

Ideal Production Parameters

P-Metric is an innovative system developed for production optimization in factories, using advanced data collection and analysis methods, learning the ideal production parameters and recommending them to the user, thereby increasing standardization and productivity in production.

Benefits

- The most suitable production parameters are determined.

- Actual production parameters and target values are monitored live.

- Standardization and productivity increase in production are provided.

Data Collecting

All process data affecting product quality are recorded in real time. All data obtained from the quality control process are mapped to the production process data and kept in the system.

Learning

By using learning algorithms, mathematical models are trained according to product types and corresponding quality characteristics to be followed. Learning process continues automatically as long as production continues.

Ideal Production Parameters

The learned models determine the most suitable production parameters for the operators and operating teams to operate according to the desired quality values or targeted production quantity. Real-time production data and target production parameters can be monitored from computers, tablets and mobile phones via a web interface.

Production Analysis

L-Metric is a system that automatically digitizes laboratory results in facilities and makes quality monitoring online and easy to analyze.

Benefits

- All past laboratory results can be viewed separately, and the relationship between the real laboratory results and the predicted values can be analyzed using statistical graphical methods.

- The dashboard enables employees at all levels to easily interpret the outputs.

Data Collecting

Ürün kalitesini etkileyen tüm süreç verileri gerçek zamanlı olarak kaydedilir. Kalite kontrol sürecinden elde edilen tüm veriler, kalite tahminleri ile eşlenerek sistemde tutulur.

Production Analysis

Realized laboratory results can be compared with ICATLabs predictions and visualized analyzes can be examined.